Quality and Service Since 2005

Glass beads/grains for highway markings, blast cleaning, alloy peening, polymer additions, construction and service sectors

AllGlass: Precision and Safety in Glass Beads

Since 2005, AllGlass has been a trusted leader in the production and supply of glass beads. We serve diverse industries including highways, manufacturing, and services, offering expertise in drop-on, premix, high-performance, peening, and filler beads.

Safety is at the heart of our mission. Our glass beads, made using high-quality recycled glass, play a vital role in road marking systems by enhancing retroreflectivity. This improvement in visibility significantly boosts traffic safety, particularly at night and during adverse weather conditions.

As an ISO14001:2015-certified company, we prioritise using recycled and low-carbon raw materials. From glass beads for road safety to glass grains for anti-skid and blasting applications, we deliver innovative, high-performance solutions tailored to your needs.

AllGlass is part of the Geveko Markings Group

For more information about Geveko Markings, please visit our website www.geveko-markings.com.

Contact Us

Please use the details below to contact Allglass.

AllGlass UK Ltd

49 Burnbrae Road

Linwood Industrial Estate

Linwood, Renfrewshire

PA3 3BD Scotland

Tel: 44 (0)1505 325564

Let our experts lead you on the way.

Our products

Glass Beads and Grains

Allglass manufactures glass beads for the highway, engineering, plastics and construction sectors to individual customer specifications.

- Premix beads for thermoplastic addition to EN1424

- Standard and high performance drop on beads to EN1423

- Standard and aerospace glass beads to EN1423 (BS6088), AMS2431 and Mil-9954

- Glass beads to aid polymer flowability

- Friction material include glass grains and corundum

- Adhesion and moisture resistant coatings available upon request

- Bead/grains sizes from 10-2000 micron

Applications

Our products cover a wide range of applications across a number of industries including:

- Highway/road marking

- Wet & dry blast cleaning

- Peening & finishing of metallic components

- Additive to thermoplastic and thermoset polymers to improve flow properties, stress loadings and abrasion resistance

- Filler for flooring materials and as an anti-skid media

- Water filtration media

Highway Glass Beads

Glass beads are an essential part of traffic safety systems. The beads increase a driver’s ability to be able to see road markings at night and in bad weather conditions due to the retro-reflective properties of a glass bead. The light is refracted in the beads, allowing it to be reflected by the road marking back towards the driver.

Glass beads are used both as drop-on beads on top of road markings and as premix beads in some types of road marking. European regulations regarding performance criteria, test criteria, quality requirement etc. can be found in the standards EN1423 and EN 1424.

Peening and Blasting Media

The AllGlass standard range of peening and blasting beads are manufactured from soda-lime glass and conform to EN1423(BS6088:1981) and Aerospace Material Specification AMS2431/6C and MIL-9954.

Our improved manufacturing process allows us to manufacture the beads with low air inclusions and a high percentage of rounds, which, together with the control we have on raw material, relates to an improved performance in impact applications.

Beads and Grain Fillers

The AllGlass standard range of beads and grain fillers can be used as additives to thermoplastic and thermoset polymers to improve flow properties, stress loadings and abrasion resistance as well as filler for flooring materials and as an anti-skid media.

Fine glass powders can also be used as filling materials for construction materials including bricks, foam glass aggregates and preformed concrete blocks.

Glass Cullet Properties

AllGlass solid glass spheres are produced from a 100% recycled standard grade of soda-lime ‘A’ glass with the following typical chemical composition characteristics:

Composition & mechanical properties

Regular chemical analysis is carried out and details of our latest results are available on request.

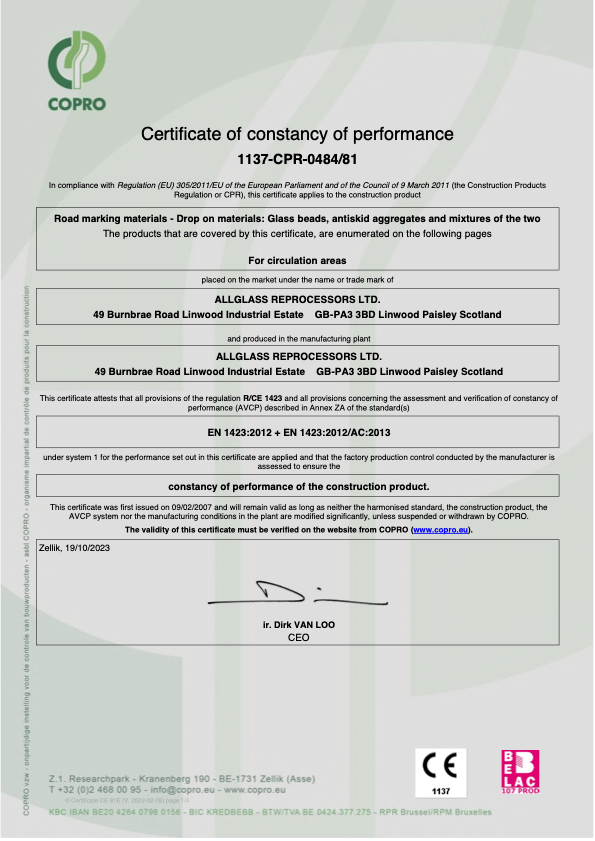

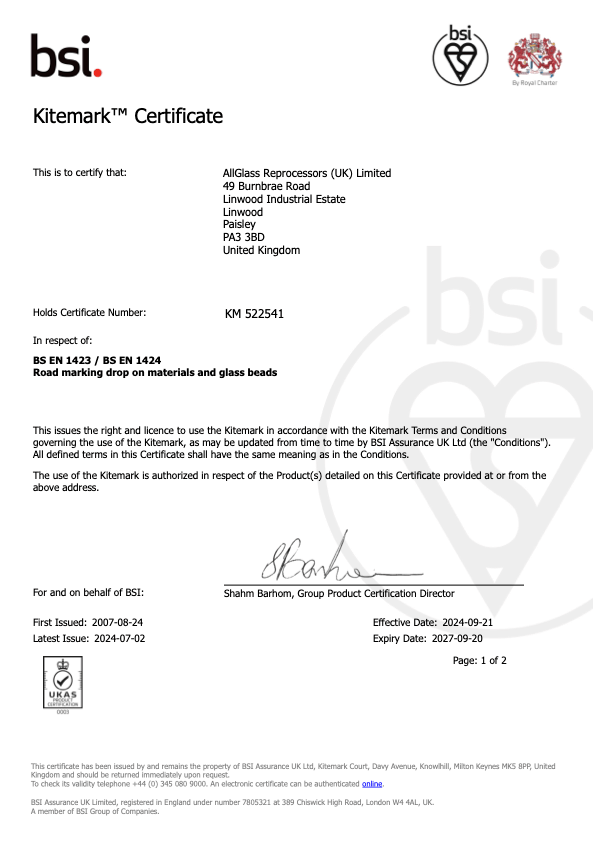

Product Standards

- EN1424 – Premix glass beads

- EN1423 – Drop on materials, glass beads, antiskid aggregates and mixtures of the two

- AASHTO M247 – Glass beads used in traffic paint

- Benor PTV881 - Drop on materials, glass beads, antiskid aggregates and mixtures of the two

- AMS2431/6C – Aerospace material specification

- MIL-9954 – Glass beads: For cleaning and peening

- Rolls Royce MLC104 CSS8 – Glass beads for use in blasting equipment

Product Certifications

AllGlass UK Ltd

49 Burnbrae Road

Linwood Industrial Estate

Linwood, Renfrewshire

PA3 3BD Scotland

Tel: 44 (0)1505 325564